IVS 2024 - Industrial Valves Summit

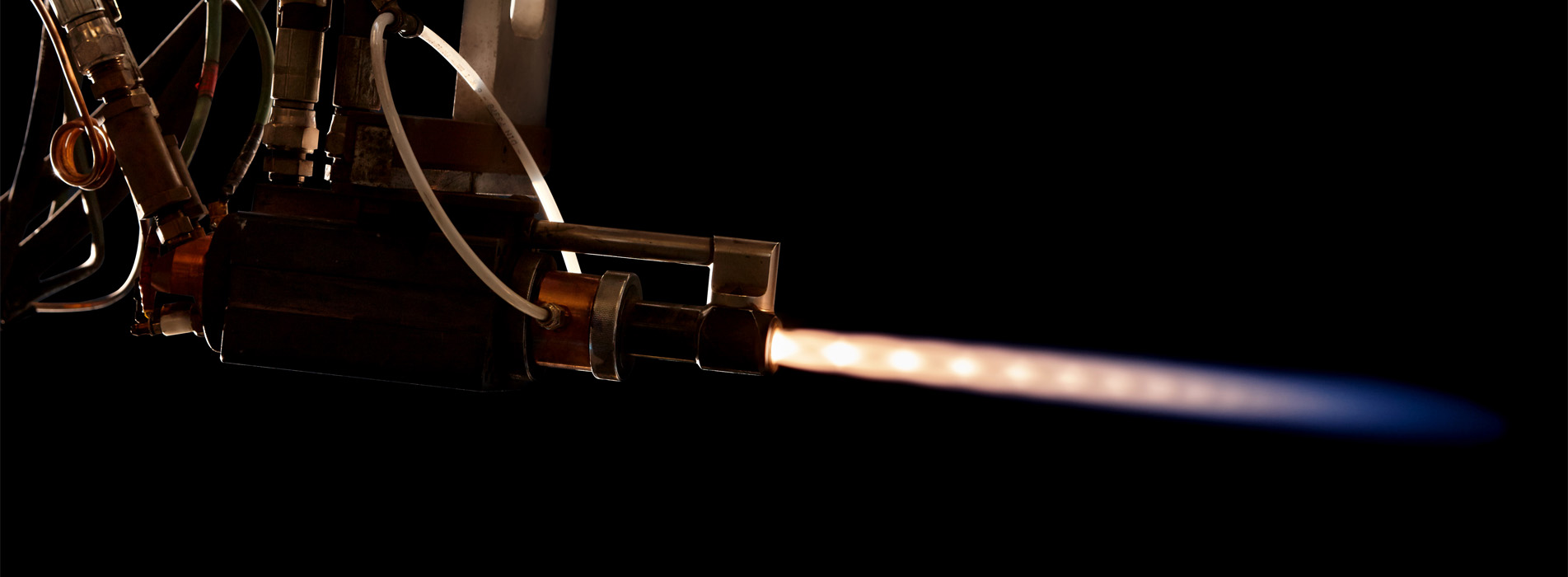

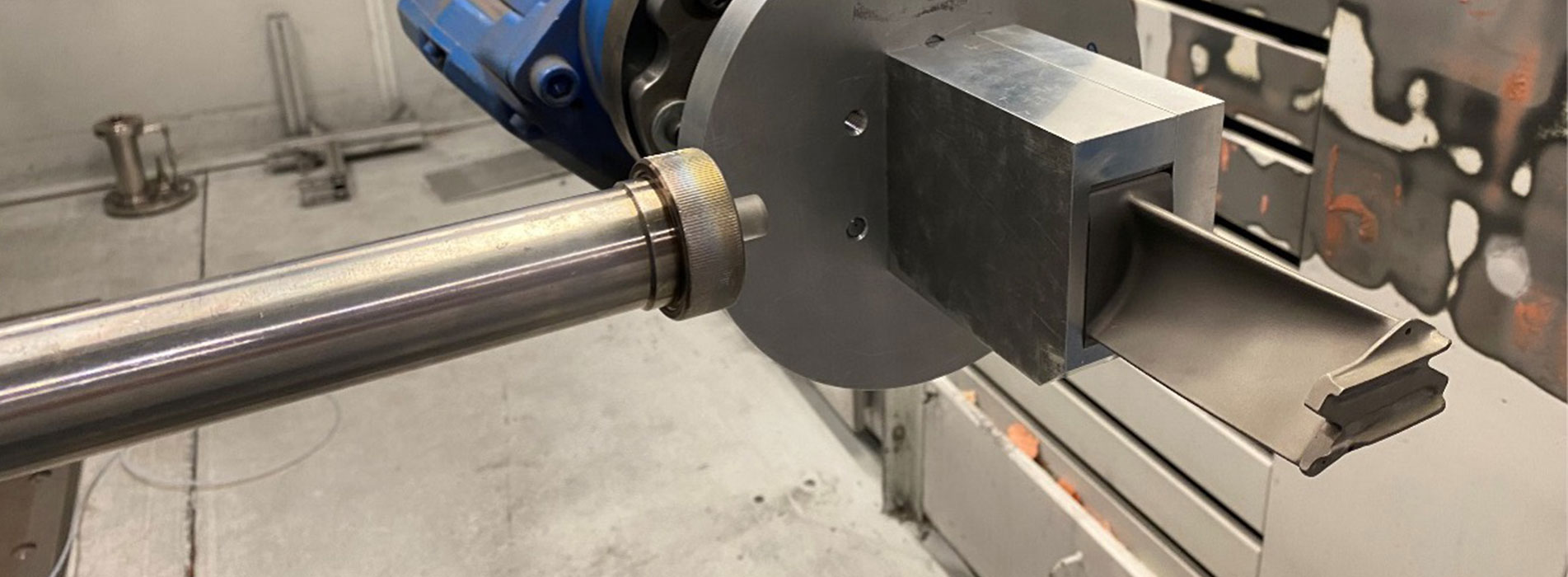

Flame Spray SpA will be exhibiting at the upcoming IVS (Industrial Valve Summit) 2024, 15-16 May, at Bergamo, Italy! Come and talk to the team about our unique range of coating technologies, we’re here to help! We hope to see you at booth A-139! Register for free at: https://registration.industrialvalvesummit.com/site/user_registration.xsp

#IVS2024 #FlameSpray #coatingtutor