Technology

Our Technologically-driven mindset propels us to constantly introduce innovative coating solutions to the market. For us, intricate components with complexcoatings are a daily challenge that lead us to advancements in technology.

Technologies used:

Innovation

We always research new technologies in the field and find inspiration in everything that surrounds us.

Flexibility

We can coat from one piece up to production run volumes, and lead times are in line with the customer’s expectations.

Reliability

We use specific, cutting-edge tools and certified methods fully compliant with the quality standards.

Steel Mills

A SHIELD AGAINST HIGH TEMPERATURES

Large loads, high temperatures, corrosion and abrasion reduce the life of steel mill components. Thermal Spray’s advanced coatings extend the life of these crucial parts by reducing replacement costs and maintenance stoppages.

We offer proven solutions that can be used on new components for protection and on used components for dimensional restoration and higher performance.

Steel Mills treated components:

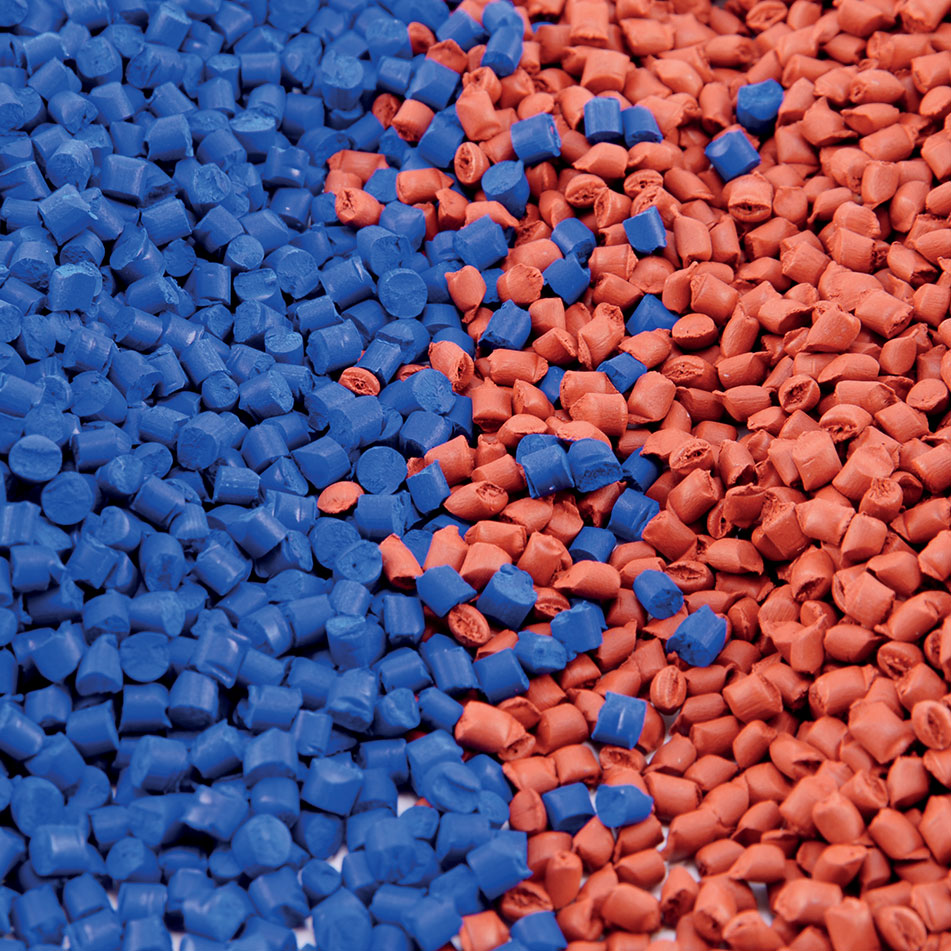

Plastics and Rubber

TOUGHER WITH TOUGH ONES

More complicated designs and higher production speeds of plastic and rubber components call for a wide range of advanced surface solutions to improve productivity. Having almost 50 years of experience in coatings and precision machining allows.

We assist customers when wear or other problems occurs. Eco friendly coatings easily replace traditional galvanic hard chrome plating.

Plastics and Rubber treated components:

Packaging

AGAINST WEAR AND TEAR

Thermal spray technologies introduced beneficial coatings to improve wear resistance and durability of parts and tools; helping to reduce maintenance costs for reliability, replacements, and increasing performance.

We're the right supplier capable of serving customer needs not only in coatings but in supplying components ready to be replaced.

Packaging treated components:

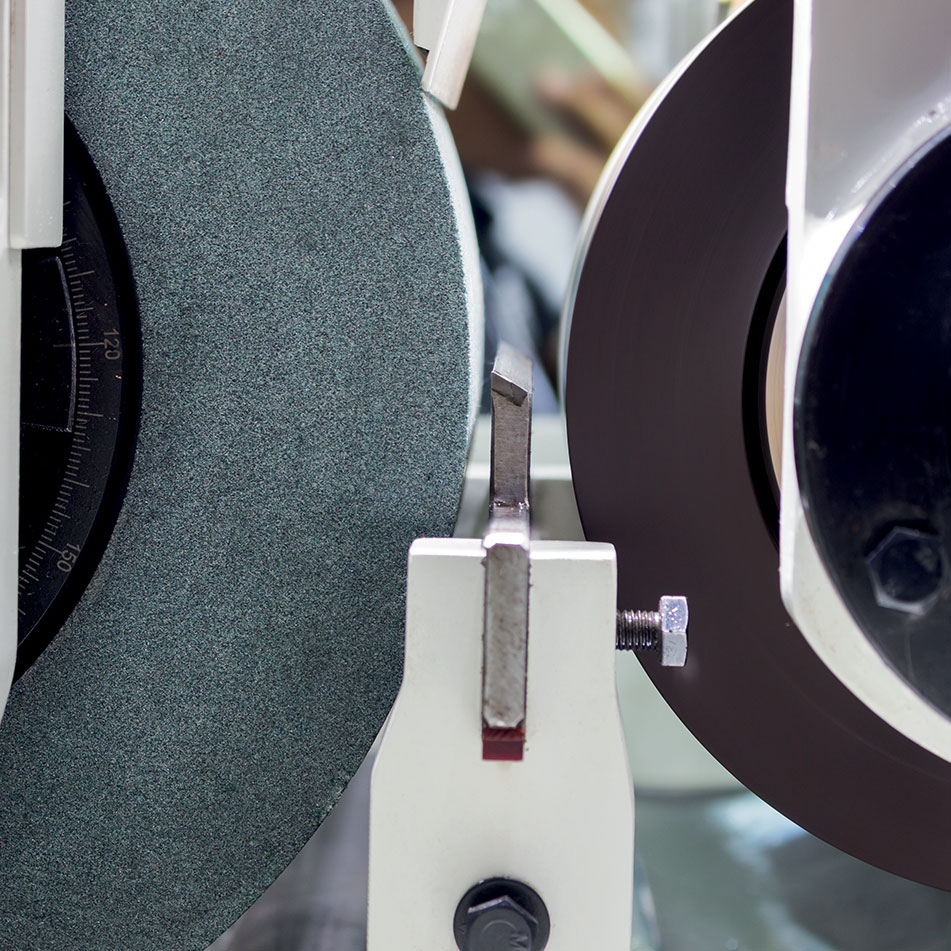

Grinding Machines

PAST EXCELLENCE JOINS FUTURE INNOVATION

Our experience in the centerless grinder sector dates back to the late 1970s when it worked with Cincinnati to develop ceramic spindles and metallic anti-friction bearings. This cooperative experience gave rise to a new division in Flame Spray for the manufacturing and reconditioning of spindles for grinding machines. When Cincinnati withdrew from the European market, our operations expanded into the retrofitting and sale of Cincinnati centerless grinders. Since the 1990s, Flame Spray has continued this retrofitting activity and supplemented its projects with state-of-the-art technology. As of 2017, over 200 Cincinnati grinding machines have been sold to highly reputable European industrial groups.

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.