Technology

Our Technologically-driven mindset propels us to constantly introduce innovative coating solutions to the market. For us, intricate components with complex coatings are a daily challenge that lead us to advancements in technology.

Technologies used:

Innovation

We always research new technologies in the field and find inspiration in everything that surrounds us.

Flexibility

We can coat from one piece up to production run volumes, and lead times are in line with the customer’s expectations.

Reliability

We use specific, cutting-edge tools and certified methods fully compliant with the quality standards.

Gas Turbines

PROTECTION EVERYWHERE AGAINST EVERYTHING

Gas turbines operate in extreme work environments where components are exposed to various types of deterioration, such as oxidation, high-temperature corrosion, thermal stress, erosion and wear. Latest-generation turbines, which run intensive work cycles, are treated with numerous coatings that make their operation possible and cut down costly maintenance.

We not only has the technologies needed to coat these components to the most stringent manufacturer specifications, but also specific know-how in precision machining and heat treatments. The countless resources that the Flame Spray group dedicates to this field enable it to provide customers with just-in-time service, be it for one piece or large-scale runs.

Gas turbines treated components:

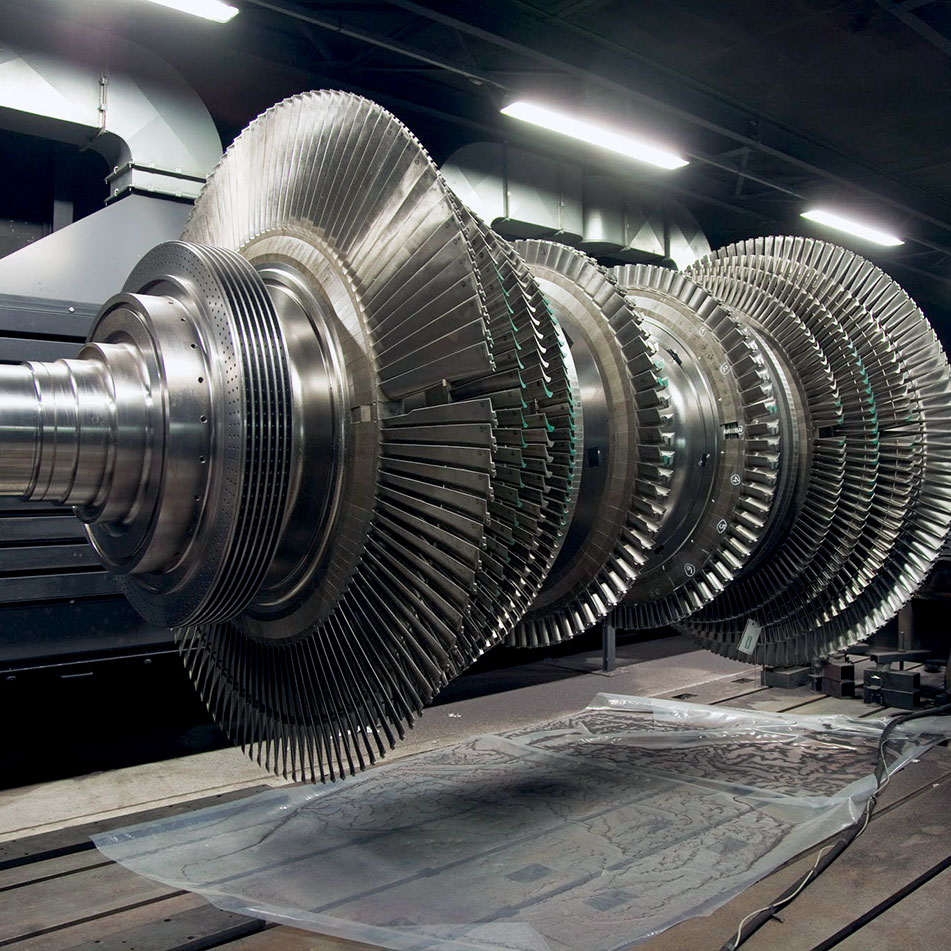

Steam Turbines

THE FLAME THAT ACCELERATES PERFORMANCE

Erosion and corrosion are seriousproblems that steam turbine users have to tackle every day. In steam turbines, the water droplets dispersed in the vapour and the particulates in the air produce dangerous erosion phenomena. Specific thermal spray coatings are the ideal way to preserve the turbines for a long time and increase their life cycle.

We have a large number of thermal spraying cabins able to optimally coat assembled large-sized turbine rotors.

Technology:

Steam turbines treated components:

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.

BEYOND COATING

A full portfolio of processes to be your one-stop shop.