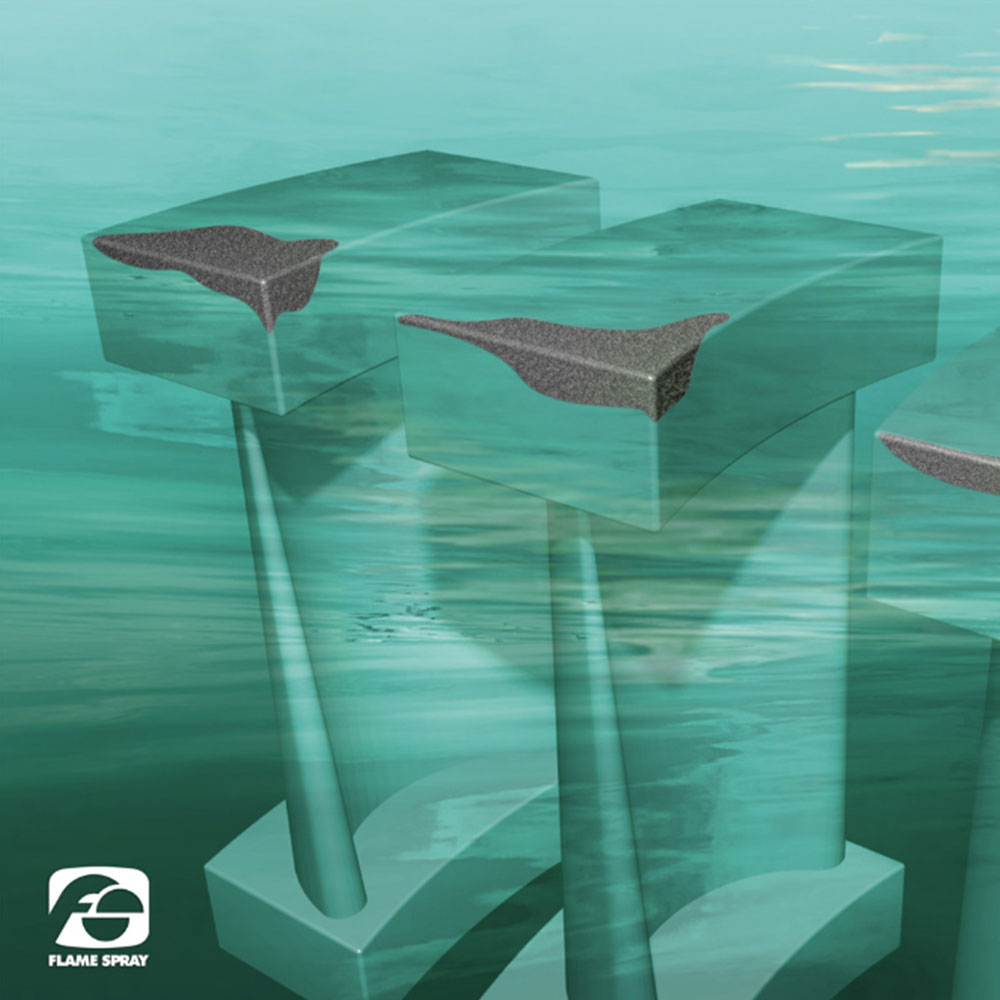

What is Diffusion coating?

Diffusion coatings are advanced metal surface protection processes where elements such as aluminum are diffused into the substrate to create a protective layer. This layer prevents oxidation and corrosion, extending the life of metal components in high-temperature environments.

The diffusion process is particularly effective for protecting components of gas turbines, engines and other parts exposed to extreme conditions. These coatings provide a barrier of protection that allows components to maintain high performance and reduces the need for frequent maintenance.

Types of Diffusive Coatings Offered by Flame Spray

Flame Spray offers a complete range of diffusion coatings designed to protect critical components in high temperature applications such as engines, turbines and fuel cells.

- Pt-Aluminide (PtAl) Coatings: Platinum aluminide (PtAl) coatings are ideal for protecting engine components from oxidation at high temperatures. These coatings maintain integrity and performance even under operating conditions up to 1,100°C, providing reliable and long-lasting protection.

- Si-Modified Aluminides: Si-modified aluminide (Si-modified Aluminide) coatings are a more economical option for lower temperature applications, such as turbines and fuel cells. These coatings are highly effective up to temperatures of around 900°C, offering an excellent balance between performance and cost.

- Standard Aluminides: Standard aluminide coatings are widely used due to their flexibility and reliability. They are ideal for protecting both internal cooling passages and external surfaces of components, such as gas turbine airfoils, burners and boiler components, up to temperatures of around 950°C.

Advantages of diffusion coating

Diffusion coatings offer a number of advantages, making them an ideal choice for components that must operate in extreme environments. Key benefits include:

- Resistance to hot oxidation: Pt-Al and silicon-modified aluminide coatings effectively protect against oxidation, preventing thermal degradation of the underlying metal.

- Resistance to hot corrosion: The protective layer created by aluminum reduces corrosion at high temperatures, improving the overall life of components.

- Increased durability: These coatings significantly extend the life of components, reducing the need for frequent maintenance and replacement.

- Improved operating efficiency: Diffusion coatings improve the efficiency and reliability of turbine engines, reducing fuel consumption and ensuring smoother, more continuous operations.

.

Applications of Diffusion Coatings

Diffusive coatings are used in a wide range of industries where high temperatures and extreme environmental conditions can compromise the life and performance of metal components. Key applications include:

- Power Generation: Gas turbines, burners, and other critical equipment.

- Transportation: Aircraft engines and other components subjected to high thermal loads.

- Fuel Cells: Components exposed to severe thermal cycling and chemically aggressive conditions.

The Flame Spray Service

Flame Spray offers innovative and reliable solutions for the protection of your components with its advanced diffusion coatings. Whether it is aircraft engines, gas turbines or fuel cells, our coatings guarantee optimal protection, durability and performance in extreme conditions.

Choose the quality and innovation of Flame Spray diffusion coatings to optimize your industrial processes and improve operational efficiency.

Flame Spray is at your service to provide you with the most advanced solutions in the field of HVAF coatings, ensuring unmatched performance and reliability for all your industrial needs.

Results

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.

Diffusion coatings F.A.Q.

Diffusion coating is a process in which metal components that will be subjected to high temperature conditions and highly corrosive environments are coated with a non-corrosive material. The process is normally done at elevated temperatures in a controlled chamber.

The most widely used coatings are chromium, aluminum or silicon material. Substrate materials usually coated include cobalt and nickel-based super alloys, steels (including carbon, alloy and stainless steels) and refractory metals, among other alloys. As a result, the base metal develops extreme resistance to corrosion, oxidation and erosion in its severe working conditions. This makes the process highly reliable, enhancing the manufacture of critical components. Diffusion coating is normally used to process gas turbine engine components (vanes, blades and cases), pump impellers, gate valves and power generation components.

Coating thickness depends heavily upon the base material and allowed diffusion temperatures, but are usually in the range of 30-100 microns (0,001” – 0,004”)