What is Cooling holes drilling?

Cooling hole drilling is a sophisticated process used to create micro-holes in gas turbine components, especially those coated with thermal barrier ceramics (TBC). These holes are crucial to ensure adequate cooling during operation, reducing the risk of overheating and improving the efficiency and life of the components

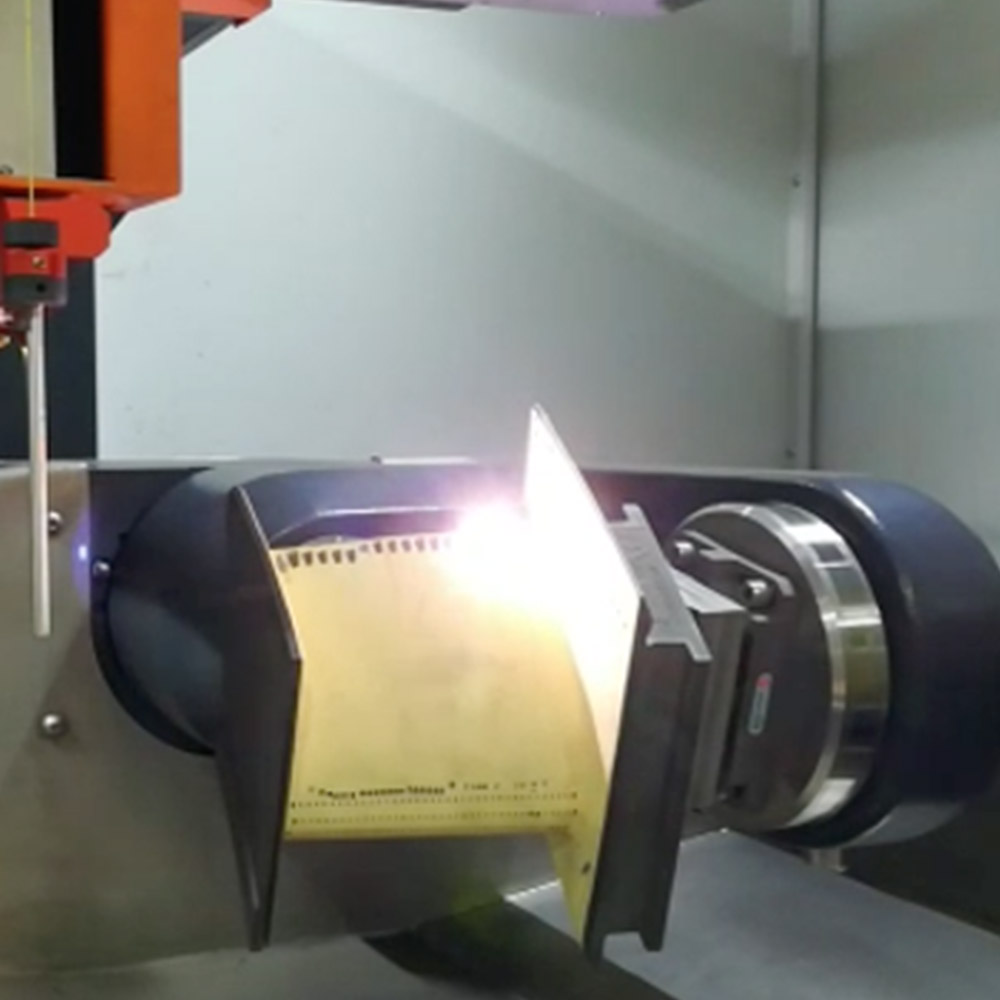

The combined system of laser ablation and electrical discharge machining is the basis of this technology, allowing the creation of holes with high precision even in the presence of thick and complex ceramic coatings.

How does the combined Laser Ablation and Electroerosion system work?

Our cutting-edge technology is based on a synergy between two key processes:

- Laser ablation :

This process uses a high-intensity laser beam to remove ceramic coatings from turbine blades and nozzles. Laser ablation is a non-contact and non-mechanical method, meaning it does not exert physical pressure on the surface. This minimizes the risk of damaging the substrate or coatings. The laser can drill with extreme precision through thick ceramic layers, preserving the quality of the component's microstructure and ensuring precise hole placement. - Electrical Discharge Machining (EDM):

Once the ceramic coating has been removed, Electrical Discharge Machining (EDM) is used to further shape and refine the cooling holes. EDM ensures exceptional accuracy in creating complex geometries, which can include inclined or multi-directional holes, without compromising the structural integrity of the material. This process is essential to achieve the specifications required by engineers, particularly in the field of fluid dynamics, ensuring optimal distribution of airflow for cooling.

Cooling holes drilling is used in:

Advantages of Cooling holes drilling

For critical TBC coated components, laser ablation performs no-contact ceramic machining that minimizes the stress applied on the ceramic top coat, preserving the integrity of delicate microstructures and critical bond coat-top coat interfaces. EDM drilling guarantees the accurate execution of complex hole shapes as designed by fluid dynamic engineers.

The FSNA machines are supplied with a camera system that allows easy adaptive programming of IGT repair components where existing holes need to be reopened after coating or weld repair.

An integrated camera and lighting system identifies the location of the holes already drilled on the part. Accurate reopening can restore the original dimension of the hole avoiding damages, clogging, and imperfections introduced by mechanical operations.

Cooling hole drilling applications

Cooling holes are used in a variety of industries, including:

- Power Generation: Gas turbine components operate in extreme environments with high temperatures and mechanical stress. Properly designed cooling holes are essential for reliable, long-lasting turbine operation.

- Aerospace: Turbines and jet engines require advanced cooling systems to prevent overheating and ensure a long operating life.

- Petrochemical Industry: Turbine components also need to be equipped with precise cooling holes to withstand the most demanding operating conditions.

The benefits of drilling cooling holes

The integration of advanced technologies such as laser ablation and EDM machining offers a number of significant advantages for the creation of cooling holes, including:

- Minimal Stress on the Coating: Laser ablation performs a non-contact removal of the ceramic coating, minimizing mechanical stress on the material and preserving the integrity of the microstructure, including the interface between the ceramic layer (Top Coat) and the metal layer (Base Coat).

- Precision and Geometric Flexibility: Thanks to EDM, it is possible to create cooling holes with complex geometries, such as specific inclinations or irregular shapes, perfectly adapting to engineering needs.

- Adaptability to Coated Components: The ability to reopen the holes after the application of TBC coatings allows to maintain optimal cooling performance, even after repair or maintenance treatments.

- Optimal Process Control: Our machines are equipped with an integrated camera system, which facilitates adaptive programming and ensures precise localization of existing holes, avoiding damage and imperfections caused by mechanical machining.

Trust Flame Spray for the creation of Cooling Holes

Using advanced technologies such as laser ablation and electrical discharge machining, Flame Spray provides precision drilling processes for gas turbine components. Our service not only ensures high performance but also extends the life of the components, optimizing the efficiency of the turbines and reducing maintenance costs.

Results

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.

Cooling holes drilling F.A.Q.

The Combined Laser Ablation and EDM System utilizes a two-step process to drill through ceramic coatings on gas turbine blades and vanes.

First, the laser ablation process is employed to remove the ceramic coating layer efficiently and precisely. Once the coating is removed, the Electrical Discharge Machining (EDM) process is applied to create cooling holes in the underlying metal substrate. This dual approach ensures clean, high-precision holes while preserving the integrity of the substrate material.

Probing and optical accessories play a crucial role in this system. Probing technology provides real-time measurement and feedback on the drilling process, ensuring accuracy and consistency in hole placement and depth. Optical accessories, such as high-resolution cameras and laser guidance systems, enable precise alignment and positioning of the drilling tool.

Together, these accessories enhance the overall precision, control, and quality of the cooling hole drilling and shaping process.

Yes, the Combined Laser Ablation and EDM System is equipped with a contact-free hole re-opening capability. After the gas turbine components are coated with ceramic material, the system can be programmed to use laser ablation to selectively remove the coating within the cooling hole area without physically contacting the substrate. This ensures that the cooling holes remain unobstructed and maintain their original geometry, contributing to optimal cooling efficiency and turbine performance