What is HVAS?

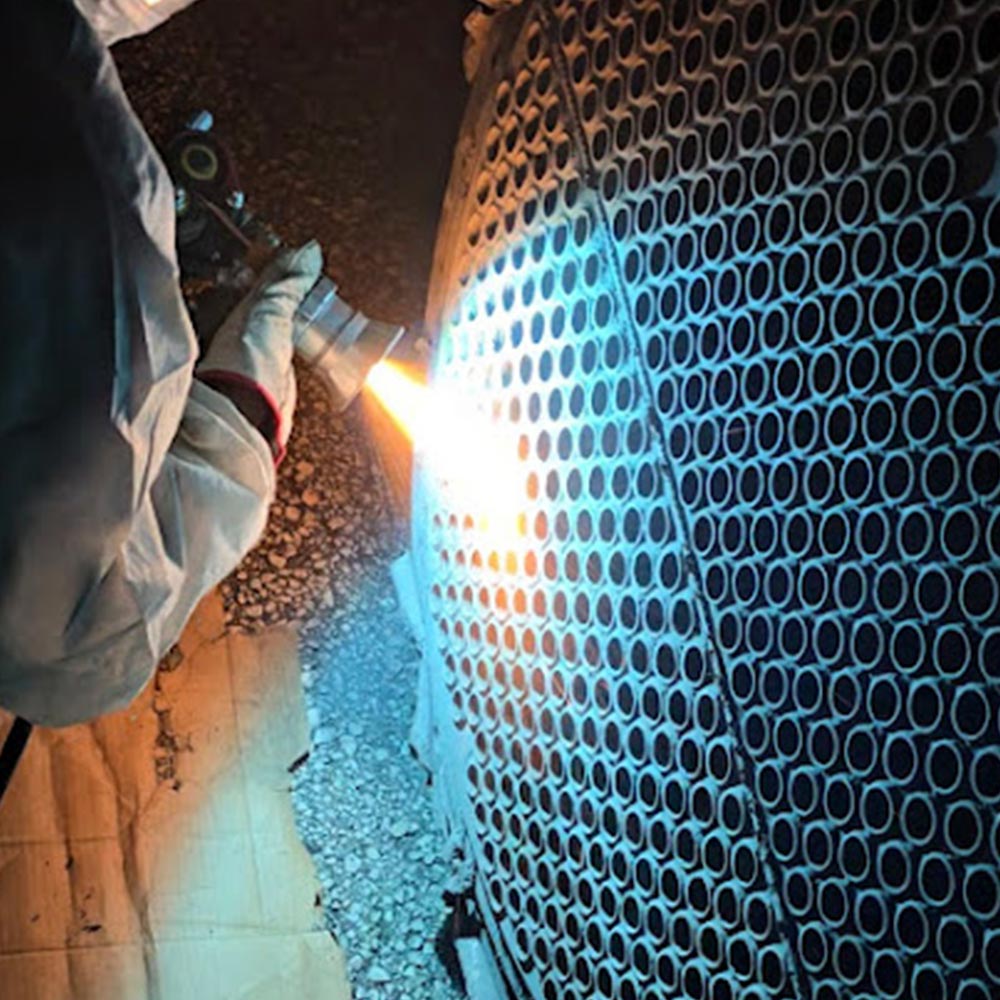

High Velocity Arc Spraying (HVAS) is an advanced thermal spray process used by Flame Spray to deposit protective metal coatings at high speed. In this process, two conductive metal wires are continuously fed and placed at close distance: an electric arc is ignited between them that instantly melts the filler metal.

The drops of molten material are immediately atomized by a jet of compressed air and projected at supersonic speed onto the substrate to be coated. The use of a De Laval nozzle allows the air flow to be accelerated to supersonic speed, generating particles at very high speed and producing a deposit characterized by a very fine and compact microstructure.

The coating is formed layer upon layer as the solid metal particles are deposited and anchored on the prepared surface. Since the heat is concentrated in the wire and minute particles, the substrate remains relatively cool (often below 100°C), avoiding thermal stress to the component. The high impact speed also favors mechanical adhesion and coating density, obtaining a resistant, low-porosity and well-cohesive layer.

Materials used in HVAS

HVAS technology uses high-quality metal wires, including materials such as Nickel-Chromium-Molybdenum (NiCrMo) superalloys and other specialty alloys. These materials – such as Inconel® or Hastelloy® alloys – are known for their exceptional resistance to aggressive oil and gas environments. The resulting coatings offer high hardness and chemical inertness, resisting erosion, sulfuric attack, naphthenic acids and other corrosive agents present in refining processes. The material selection is optimized based on the service: for example, Ni-Chromium-Molybdenum alloys for high-temperature acid environments, or zinc-aluminum alloys for cathodic protection in lower-temperature applications. Flame Spray will help you select the right alloy and wire for your specific plant conditions.

HVAS is used in:

Typical applications in the Oil & Gas sector

Flame Spray's HVAS solution is designed to protect a wide range of critical equipment in the Oil & Gas industry, without the need for disassembly. In refineries and petrochemical plants, distillation columns, pressure vessels, reactors and heat exchangers are constantly exposed to aggressive mixtures of hydrocarbons, organic/inorganic acids, salts and high-temperature steam. These extreme conditions cause accelerated internal corrosion, reducing component life, undermining operational efficiency and increasing extraordinary maintenance costs and plant downtime.

Typical applications for HVAS on-site corrosion protection coating include:

- Distillation columns (atmospheric and vacuum): Protect column internals from corrosion by naphthenic acids and high-temperature sulfidization. A field-applied NiCrMo alloy coating prevents wall thinning and significantly extends equipment life, avoiding the need to replace the cap or internal trays.

- Hydrocracking and hydroprocessing reactors: Coating of internal surfaces to resist acidic environments (low pH) and the presence of sulfur, chlorides and other corrosive species. HVAS technology provides on-site corrosion protection for distillation columns and reactors operating in “sour service” conditions, acting as an impermeable metallurgical barrier that protects the base metal without requiring expensive structural alloys

- Heat exchangers and condensers: Application of anticorrosive coatings on tube plates, tube bundles and external jackets subject to corrosion. For example, it is possible to coat the tube plate of an exchanger in situ to protect it from acidic water or fluids containing H₂S, avoiding leaks and contamination. An in situ coating on heat exchangers allows to restore and improve the resistance without having to remove the unit from its housing.

< - Refinery tanks and pipelines: Protection of storage tanks, separators and pipelines subject to atmospheric or chemical corrosion. HVAS can apply anti-corrosion alloy layers to the inside walls of corrosive process tanks (refinery tank protection), for example in bottom areas subject to acid water or deposits, prolonging the integrity of the vessel. Similarly, critical pipe runs or valves can be coated in place to increase their resistance to aggressive media.

In sintesi, i rivestimenti anticorrosivi on-site eseguiti con tecnologia HVAS rappresentano una soluzione altamente efficace per la protezione di colonne, serbatoi, scambiatori e altre refinery equipment critiche.

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.