HIP Technology

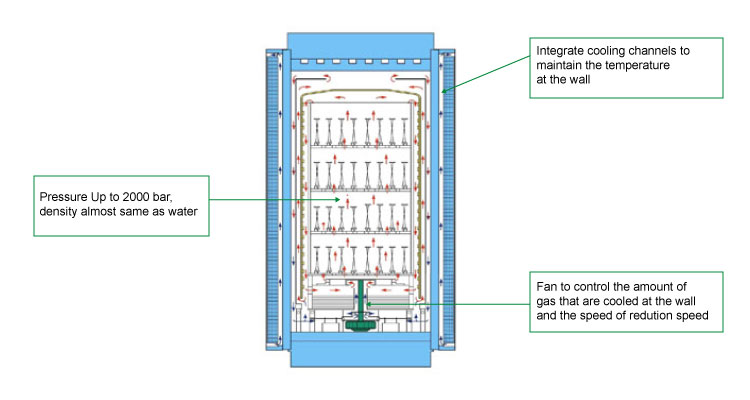

Hot Isostatic Pressing (HIP) is a manufacturing process based on the simultaneous application of high pressure and high temperature in an inert gas environment (typically argon). In a HIP plant, the components are inserted into a pressure chamber (autoclave) equipped with an internal oven; the combination of pressure up to ~2000 bar and temperatures up to ~2000 °C allows to eliminate internal porosity and to reach the theoretical density of the material (≈100% of the maximum density).

During the HIP cycle, conducted in an inert atmosphere to avoid oxidation, the parts are typically treated at about 80–90% of their melting temperature, a condition in which creep, atomic diffusion and recrystallization phenomena occur that weld the internal micro-cavities (porosity, microcracks), leading to a denser and more homogeneous material. The result is a component with superior mechanical properties and less dispersion of performance from part to part.

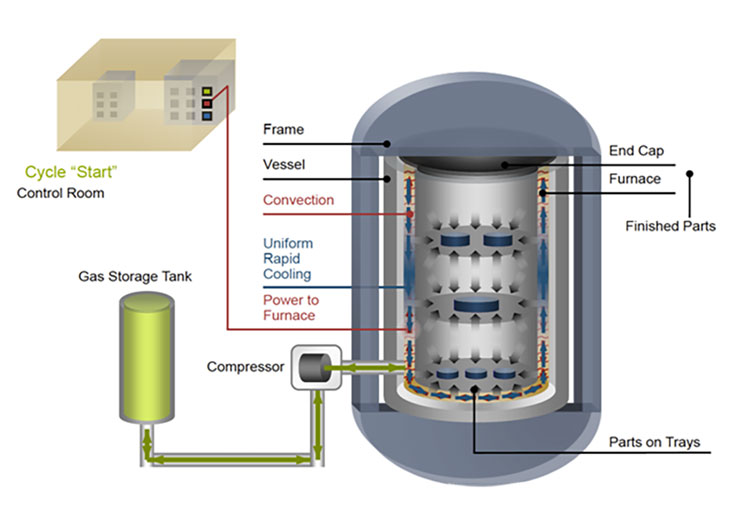

The HIP process is a batch process and each cycle is strictly controlled by automatic systems (computer/PLC). After loading the parts into the chamber, the system sequentially closes the pressure vessel, evacuates the air and introduces the inert gas, then ramps the pressure and temperature to the desired setpoints, holds them at the maximum conditions for a defined time, and finally gradually cools and depressurizes before unloading the machined parts.

Modern HIP systems allow for high precision in cycle control: specific heating, pressurization, residence times and cooling speed profiles can be programmed to ensure repeatable results and targeted microstructures in each cycle. For example, HIP equipment offers excellent thermal uniformity and advanced digital connectivity systems, giving the operator the flexibility to manage and track the entire production process and the final product characteristics.

HIP machines

Hot isostatic pressing systems consist of robust high-pressure autoclaves integrated with resistive furnaces and auxiliary systems (gas compressors, vacuum and cooling pumps, heat exchangers, control valves), all managed by dedicated electronic controls and software.

Sizes and capacities range from laboratory systems to large industrial plants: pressure vessels (hot chambers) can have useful diameters from ~25 cm up to over 2 m and heights up to ~4 m, allowing for the treatment of large components or high production volumes in a single cycle. Commercial HIP systems typically operate at pressures from ~1000 to 2000 bar (15,000–30,000 psi) and temperatures up to ~1400–2000 °C, depending on the model and the type of heating element (molybdenum furnaces for T≤1400 °C, graphite for higher temperatures).

The most common configuration is with vertical orientation (loading from above via a loading trolley), but there are also HIP systems with a horizontal or tilting chamber, used to facilitate the insertion of particularly bulky pieces or for specific plant engineering needs.

From a construction point of view, modern HIP systems adopt advanced solutions to ensure safety and durability despite the extreme operating conditions. The industry-leading design includes pre-stressed steel vessels wrapped with high-strength cables (wire-wound vessel) housed in a robust yoke frame. This pre-stressed construction externally resists the internal pressure and prevents crack propagation in the shell, providing the safest pressure containment system ever designed.

These chambers meet the stringent international codes for pressure vessels (ASME Sec. VIII Div. 3, PED 2014/68/EU, etc.) and are designed according to the “leak-before-break” criterion, that is, to deform and leak gas in a controlled manner in the event of overload instead of abruptly failing. This ensures a high operational safety margin and a long fatigue life (over 30,000 design cycles).

Automation and control aspects are also taken care of in detail: today's HIP systems integrate advanced sensors and digital connectivity to monitor temperatures and pressures in real time, with software that allows cycle traceability and productivity optimization.

Features such as automated loading/unloading of part baskets and integration with existing production lines can be implemented to increase throughput and operational safety. Furthermore, construction features such as the thermal uniformity of the oven and forced gas circulation ensure homogeneous treatments across the entire load, while redundant valve and interlock systems guarantee protection for both operators and equipment at every stage of the cycle.

HIP treatments and the URC (Uniform Rapid Cooling) process

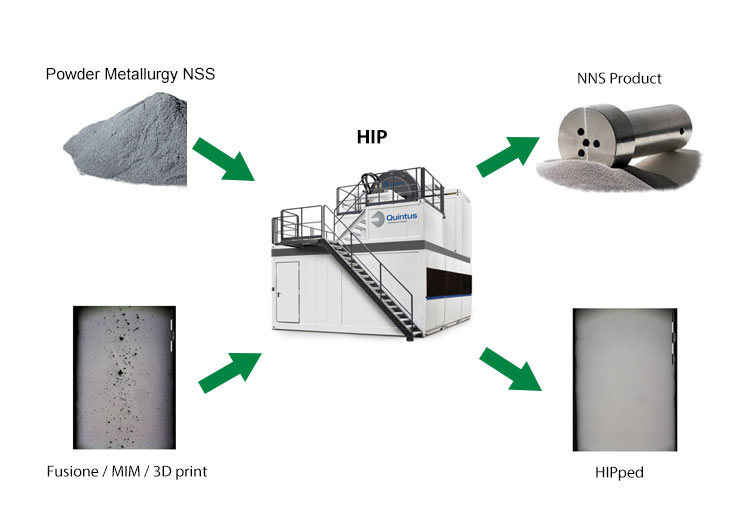

HIP technology is used in a variety of treatments on metallic and ceramic materials in order to improve their characteristics through densification. Some typical applications include:

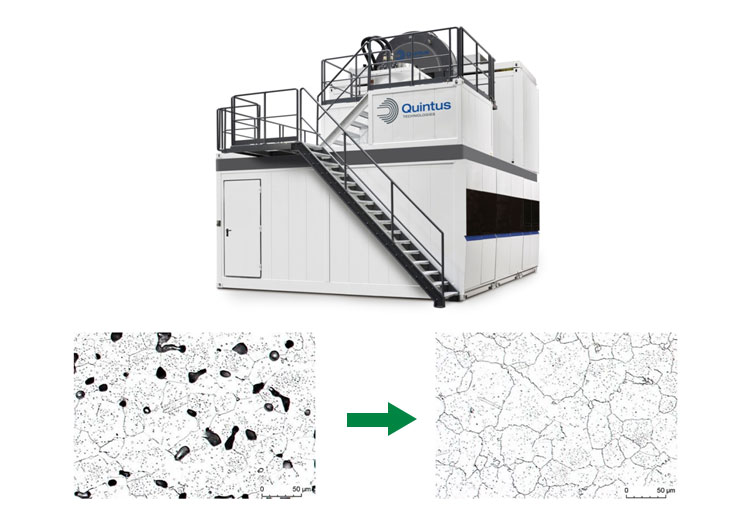

- Densification and “healing” of castings: elimination of micro-porosities from metal castings (e.g. titanium alloys, superalloys, high-strength steels) to increase their strength and reliability. Through HIP it is possible to fill or close the solidification voids inside castings or sintered parts, reducing or eliminating internal defects detectable by non-destructive testing (NDT). In this way, critical components that had internal porosity or micro-cracks can be recovered instead of being scrapped. HIP is widely used as a “repair” technology to heal internal defects in castings and sintered parts, eliminating internal voids and cracks and improving the overall metallurgical quality.

- Consolidation of metal powders in Near Net Shape (NNS): production of parts with a near-final shape by pressing powders in hermetic capsules. In the PM-HIP process (Powder Metallurgy + HIP), metal or ceramic powders are inserted into a container (capsule) with the shape of the final part; HIP simultaneously sinters and compacts the material, obtaining a dense component with a near-final shape, reducing subsequent processing. This technique allows for the production of complex parts (even composites or difficult-to-cast materials) with a fine microstructure and no residual porosity. Similarly, HIP can densify pre-sintered parts (derived from traditional powder metallurgy or additive manufacturing) bringing them to maximum density and integrity.

- Optimization of Additive Manufacturing (AM) components: Parts produced by metal additive manufacturing often present intrinsic defects such as porosity from lack of fusion, microstructural anisotropy and residual stresses. The application of a post-production HIP cycle allows to eliminate internal porosity and discontinuities, increasing the fatigue resistance and mechanical properties of the material. Furthermore, HIP reduces the anisotropy of additive materials: after treatment, the component is more isotropic and homogeneous, with less dispersion of properties and more predictable behavior. This is essential to qualify AM parts in critical sectors (aerospace, medical) where maximum reliability is required.

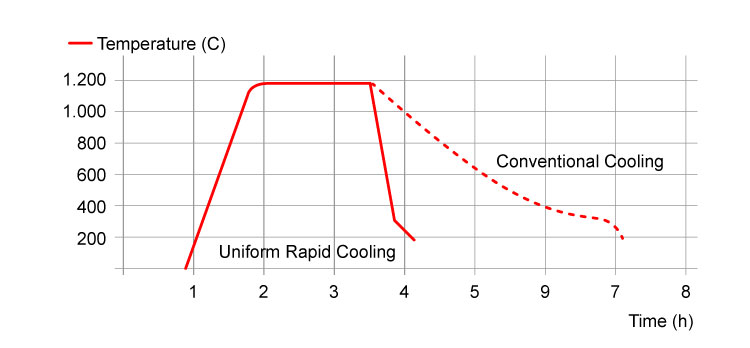

An important evolution in HIP treatments in recent years is the introduction of the URC (Uniform Rapid Cooling) process, which allows for high-pressure heat treatments to be carried out inside the autoclave itself. In a system equipped with URC, at the end of the high-temperature and pressure holding phase, the inert gas is forced to circulate through an integrated heat exchanger, allowing for rapid and uniform cooling of the entire load.

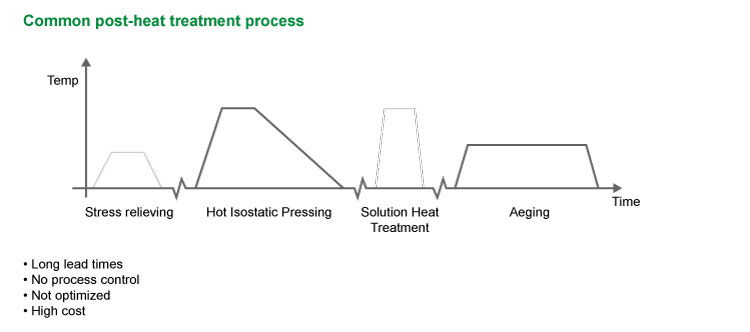

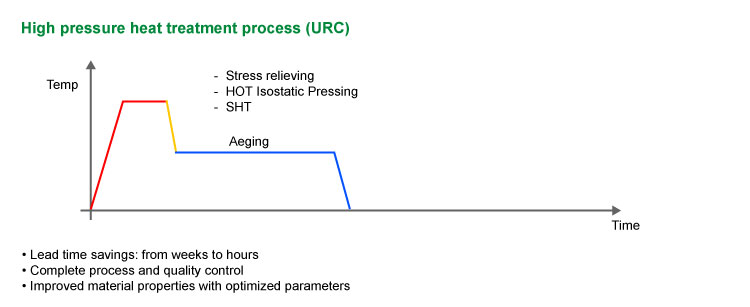

This accelerated cooling in a pressurized atmosphere (inerts) paves the way for combined HIP+heat treatment cycles, in which, for example, the material is tempered or solubilized immediately after densification, without having to extract the piece and transfer it to an external oven. The URC® technology, patented by Quintus, guarantees precise control of the thermal gradient during cooling: the forced convection of the high-pressure gas on the heat sink allows for the setting of customized cooling curves, avoiding thermal shocks and ensuring process repeatability. For applications requiring extremely high cooling rates, the URQ (Uniform Rapid Quenching) variant is also available, which achieves true press hardening with cooling rates comparable to those of conventional gas or oil quenching, minimizing residual stresses in the workpieces.

From a microstructural point of view, HIP cycles with rapid cooling under pressure (High Pressure Heat Treatment, HPHT) allow to obtain structures and properties that would otherwise be unattainable with separate processes. For example, thanks to URC it is possible to avoid the coarse-grained recrystallization that would occur with slow cooling in the furnace, or to retain reinforcing precipitates in solution up to lower temperatures, in practice realizing a tempering under pressure. Numerous studies highlight how a well-set combined HIP+URC cycle can give better characteristics to materials compared to the traditional HIP sequence followed by external heat treatment. Furthermore, the in situ heat treatment takes place in a pure inert atmosphere (systems such as Quintus Purus® guarantee minimum levels of residual O₂/H₂O), avoiding oxidative phenomena and decarburization: this results in cleaner and defect-free metallurgical surfaces and matrices. In summary, the availability of URC/URQ in a HIP plant offers greater process flexibility (combined densification and treatment cycles) and better control of final properties, especially for alloys requiring rapid cooling or particular thermal profiles.

Benefits offered by HIP technology

The adoption of hot isostatic pressing on metal and ceramic components brings a series of benefits in terms of performance and metallurgical quality of the treated materials:

- Improved mechanical properties: By eliminating internal porosity and other discontinuities, HIP increases the static mechanical strength (yield, ultimate tensile strength) and ductility of the material. The statistical dispersion of these properties from batch to batch is also reduced, since internal defects (causes of local weakening) are eliminated. In many cases, an increase in hardness and a better response to subsequent heat treatments is also observed due to the more homogeneous microstructure.

- Increased fatigue resistance and service life: The presence of porosity or inclusions is often the origin of fatigue cracks in metals subjected to load cycles. HIP, by removing these internal defects, dramatically increases the fatigue resistance of the component. Critical components (e.g. turbine blades, structural joints, medical implants) treated with HIP show longer fatigue lives and greater reliability in operation. This translates into longer service life of the parts and extended maintenance intervals.

- Recovering defective castings and parts: One of the significant economic benefits of HIP is the ability to salvage expensive parts that have internal defects. For example, light alloy castings or arms with microporosity that would otherwise make them scrap can be densified with HIP, obtaining parts that meet specifications without remelting them from scratch. This reduces scrap and production costs, especially for large parts or high-quality materials (aeronautical superalloys, titanium, etc.). After HIP treatment, components typically pass previously failed non-destructive testing (X-ray, ultrasound) with flying colors, thanks to the elimination of internal indications (voids, cracks) that such testing would have detected.

- Improved metallurgical integrity and optimized microstructure: HIPed components have a healthier internal structure: more uniform crystal grain, absence of vacancies or solidification defects and often a reduction in residual stresses. In the case of additive manufacturing or welding materials, HIP alleviates anisotropy and produces a more isotropic and homogeneous material in all directions. Furthermore, the possibility of combining heat treatments (via URC) means that the desired microstructure (e.g. quenched and tempered) can be directly achieved during pressing, further improving final performance. In critical applications, this translates into greater component reliability and predictable behavior under load, which is crucial for sectors such as aerospace, energy and biomedical.

In conclusion, HIP technology represents a key process to obtain high-performance materials free from internal defects, effectively combining densification and advanced heat treatments. Thanks to continuous developments (such as Uniform Rapid Cooling) and the experience gained in fine control of cycles, HIP is now used in the most demanding sectors to increase the metallurgical quality of products and ensure their longevity in service.

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.