HIP technology in the aerospace context

Hot Isostatic Pressing (HIP) is an advanced thermomechanical process used to densify metallic and ceramic materials by simultaneously applying high isostatic pressure (typically up to ~100-200 MPa) and high temperature (up to ~2000 °C) in an inert environment (usually argon gas). This combination of heat and uniform pressure helps eliminate internal porosity in parts, improving their metallurgical properties.

In the aerospace industry, known for its extreme demands on performance and safety, HIP has long been used to ensure materials free from internal defects and consistent characteristics, essential for high operational integrity components. In fact, even minimal microporosities resulting from casting or sintering can compromise the mechanical resistance of a critical component: for example, the presence of voids significantly reduces the fatigue resistance and reliability of parts subjected to cyclic loads.

Materials treated with HIP

From the point of view of treated materials, HIP technology finds application on a wide range of alloys used in the aerospace field: nickel-based superalloys (used in turbines), titanium alloys (for structural components and disks), high-strength special steels, aluminum and cobalt alloys, as well as metal or ceramic matrix composite materials.

During the process, the component is placed in a pressure vessel and subjected to a controlled thermal cycle; the high-pressure inert gas exerts uniform compression over the entire surface of the piece, allowing the material to deform plastically when hot and fill the internal cavities. The creep and solid-state diffusion mechanisms allow the pores to gradually close, up to complete diffusion bonding of the void surfaces in the final stages of the cycle. The result is a component with virtually full density and a more homogeneous microstructure, free from the original fusion or sintering defects.

The metallurgical and mechanical advantages obtained are significant: HIP increases the structural integrity and robustness of the treated materials, leading to improvements in fatigue resistance, ductility and fracture toughness compared to the cast or sintered state. It also reduces the variability of mechanical properties between similar pieces (less scatter), ensuring more predictable and uniform performance.

In the aircraft industry, the introduction of HIP since the 1970s has increased the quality and reliability of critical components such as turbine blades and engine structures: today, all titanium components, those produced by additive manufacturing, and many nickel superalloy parts intended for modern jet engines must be HIP-treated before use. In summary, hot isostatic pressing has established itself as a key technology to meet the demanding specifications of the aerospace industry, ensuring that each critical part has the highest density and microstructural integrity possible.

The automation and control aspects are also taken care of in detail: today's HIP systems integrate advanced sensors and digital connectivity to monitor temperatures and pressures in real time, with software that allows for cycle tracking and productivity optimization.

Features such as automated loading/unloading of part baskets and integration with existing production lines can be implemented to increase throughput and operational safety. Furthermore, construction features such as the oven's thermal uniformity and forced gas circulation ensure homogeneous treatments across the entire load, while redundant valve and interlock systems guarantee protection for both operators and equipment at every stage of the cycle.

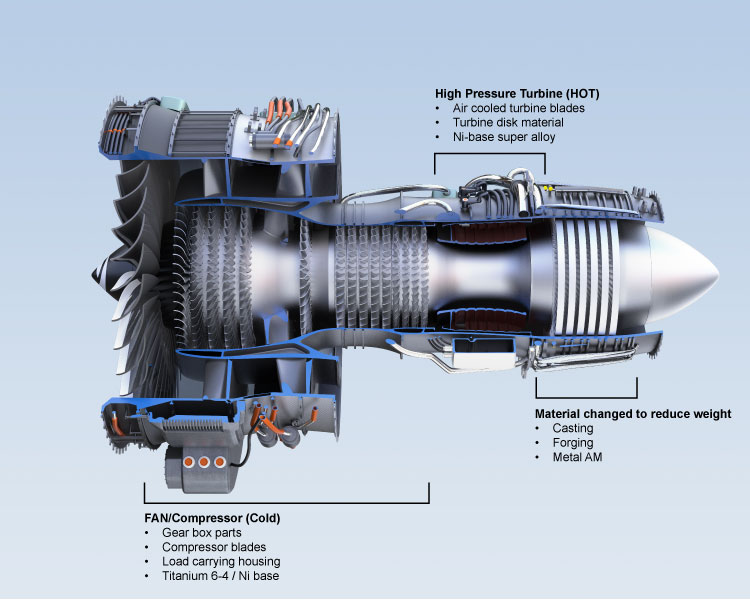

HIP Applications on Aircraft Engine Components (Turbines)

In aircraft engines – especially turbojets and turboprops – HIP technology finds wide application to improve the performance and operating life of various turbine components.

The main use cases are examined below:

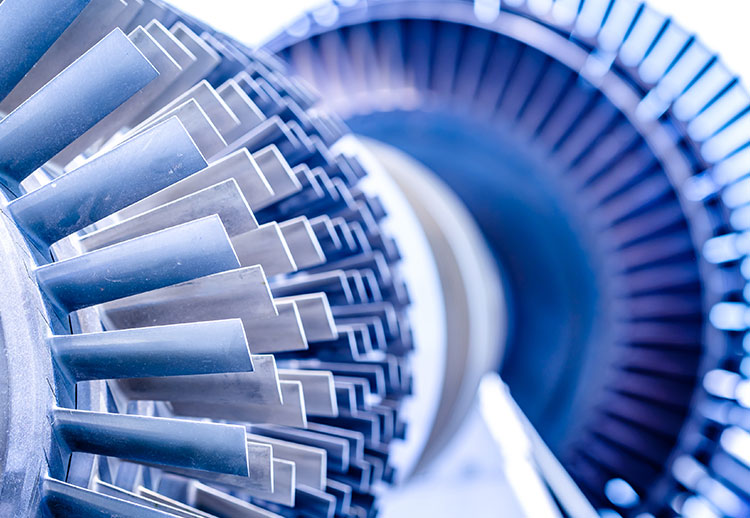

- High (and low) pressure rotor blades are typically cast from nickel superalloys using the investment casting (chill casting) process, which can leave solidification micro-voids within the material. Treating these blades with HIP allows the internal micro-cavities to be closed and any residual micro-cracks to be eliminated, producing a more compact and discontinuity-free microstructure.

From a metallurgical point of view, this translates into significant microstructural benefits: the removal of porosity increases the uniformity of the alloy and avoids localized weak points. In operation, a HIPed turbine blade shows a significant increase in fatigue strength (both low-cycle and high-cycle fatigue) due to the absence of defects that could initiate cracks under cyclic stresses. Creep resistance (slow deformation under hot load) and creep fracture life are also improved, as casting voids – which act as nuclei for creep cavitation – are eliminated. In practice, a rotor blade cast and then densified via HIP can achieve mechanical properties comparable to those of a high-quality forged component, while maintaining the complex geometry that can only be achieved by casting. This treatment therefore increases the in-service reliability of rotor blades, reducing the risk of sudden failures under extreme thermomechanical stress conditions.

- Stator vanes are the fixed blades that channel the flow of gases between the various turbine impellers. They are also often made of superalloys (Ni or Co based) by precision casting, given the complexity of the shapes with internal cooling channels. The HIP treatment on these components mainly aims at structural consolidation: the simultaneous pressurization and heating eliminates the internal casting voids, closing micro- and macro-scopic porosities and joining any internal discontinuities by solid state diffusion. This leads to a more compact and uniform structure, free from intrinsic defects. The reduction of internal defects translates into several practical benefits. First of all, the rejection rate of castings is drastically reduced: many stator vanes that presented unacceptable porosities to non-destructive testing can be recovered with HIP, the only effective method to "repair" porous castings. Furthermore, the treated blade has more consistent mechanical properties (less variability between pieces) and better resistance to thermal fatigue, which is essential given that these components undergo strong thermal gradients and static stresses. HIP, by improving the homogeneity of the material, therefore allows to optimize the structural integrity of the stator blades and to increase their operating life without increasing the safety factor (weight). In other words, more reliable and durable fixed blades are obtained, with fewer defects and guaranteed performance within narrower ranges.

-

Turbine discs are the circular rotors to which the blades are attached; they transfer the power obtained from the expansion of the gases to the engine rotor. High-pressure discs work in harsh conditions: high temperatures and very intense centrifugal stresses. Traditionally, these discs are forged from ingots or preforms obtained by powder metallurgy, in high-strength nickel or titanium alloys. In both cases, HIP technology intervenes to ensure the total absence of internal porosity in the disc material. In the case of discs obtained directly from casting, a post-casting HIP treatment eliminates shrinkage voids or internal discontinuities resulting from solidification, making the material more robust and homogeneous throughout the volume. PM (from Powder Metallurgy) discs, made by hot isostatic compaction of powders in sealed capsules, obviously also owe their very existence to the HIP process: this allows the metal powders to be consolidated into a dense and cohesive body, which is then mechanically machined or forged into a final shape. In both approaches, the absence of internal defects is critical. A HIPed turbine disc offers greater structural strength and toughness: free of voids, the disc better withstands extreme stresses, avoiding cracks originating internally. This allows designers to push closer to the limits of the material (reducing oversizing due to imperfections) without compromising safety. Several aircraft manufacturers, in fact, formally require that critical discs be subjected to HIP or come from processes that incorporate it, with a view to guaranteeing maximum structural integrity. Ultimately, HIP on turbine discs eliminates defects that might otherwise propagate during service, ensuring stronger, longer-lasting and more reliable rotors.

Other turbine components treatable with HIP

In addition to blades and disks, many other aircraft engine components benefit from hot isostatic pressing. In general, any critical part made by casting, sintering or 3D printing can be a candidate for HIP treatment to improve its characteristics.

For example, engine crankcases and housings (such as compressor cases, turbine shafts or support structures in titanium, aluminum or nickel alloys) are often obtained by sand or gravity casting; a HIP cycle on these elements allows to eliminate porosity and internal defects in thick sections, ensuring full structural integrity especially at the points of connection with other structures. This is important for components that have to withstand static loads and vibrations (for example, the housing of a turbine or the supporting structure of a transmission gear): thanks to HIP, the fatigue resistance of such parts is improved and the propagation of cracks from hidden defects is prevented.

Additive Manufacturing and HIP

Another rapidly growing area is that of additive manufacturing (AM) for engine components: complex parts such as fuel nozzles, fluid ducts and brackets are now produced with metal 3D printing (EBM, DMLS, etc.) and are used in latest-generation turbojets. These components intrinsically present residual micro-porosities and structural anisotropies due to the additive process. HIP has established itself as a mandatory step for such parts: through the complete densification of the material, the fatigue resistance and robustness of the AM parts are increased, eliminating internal defects and making the microstructure more isotropic and uniform. For example, a 3D-printed fuel nozzle and then treated with HIP shows significantly superior mechanical properties and durability compared to the raw state, making it suitable for critical applications in the combustion chamber. In summary, from combustor hardware (such as injectors, swirlers) to sealing structures (nozzle segments, sealing rings) to elements such as additively or powder-manufactured blisks, hot isostatic pressing is a critical finishing step to ensure that each engine component achieves the maximum metallurgical quality required by aircraft standards.

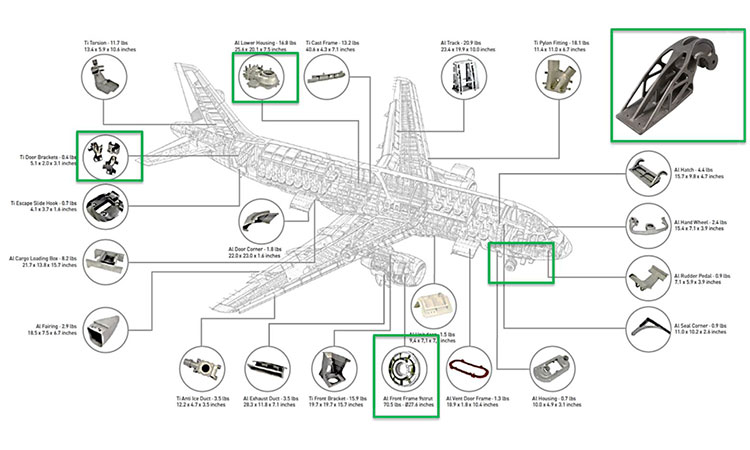

Other HIP-treatable aircraft components

The use of HIP in the aerospace industry extends beyond the engine to many structural components of the aircraft. In these cases the main objective is to ensure the integrity of the material and improve the fatigue resistance of parts that withstand high mechanical loads during service. Here are some relevant examples:

Landing gear

Landing gear are among the most critical structural components of an aircraft, having to absorb severe impacts and stresses during every takeoff and landing. The gear legs and their joints are often made of high-strength alloy steels or titanium alloys, either by forging or casting. In the case of large spindle-shaped elements (such as bearings, attachments and gear knuckles), even small internal porosities can be a serious crack initiation point under repeated loading. For this reason, several manufacturers are using HIP on light alloy or titanium landing gear components, especially when produced by casting or near-net shape methods. Hot isostatic pressing eliminates internal defects in these massive components, ensuring a dense, homogeneous structure. This leads to a significant improvement in fatigue life under cyclic loading and landing shocks, increasing operational safety. For example, titanium alloy structural landing gear joint castings, after HIP treatment, showed significantly longer fatigue lives and less spread in test results, indicating a more consistent material. Furthermore, HIP allows safety factors related to potential internal defects to be relaxed: a densified landing gear saves weight, as it does not require oversizing to compensate for metallurgical uncertainties. Ultimately, HIP helps ensure that landing gear – which must “perform flawlessly every time” under extreme conditions – has the required robustness and reliability.

Aircraft Structural Hinges and Joints

Airframes feature numerous hinges, joints and connections that connect moving parts or structural sections (think of door and hatch hinges, control surface joints, wing attachments or fuselage-to-wing connections). These components are often made of light alloys (aluminium or titanium) to reduce weight, using precision casting processes to achieve complex geometries with less machining. Examples include door hinges or titanium structural nodes that join spars and frames. Such critical castings benefit greatly from HIP treatment: the elimination of internal porosity ensures total metallurgical integrity, a critical requirement because a hidden defect in a structural joint could propagate with vibration and flight loads, leading to catastrophic failure. With HIP, the mechanical fatigue properties of these parts are optimized, as crack initiation sites are removed. For example, very precise structural components made of aluminum or titanium alloys – such as wing mounts or engine mounts – are HIPed to ensure that each one achieves the maximum strength and toughness available from the material. Parts made from sintered or additively manufactured metal powders (a growing trend for complex structural parts) are also HIPed to achieve full density. In short, HIP is applied to structural hinges and joints to “optimize the mechanical properties and fatigue life of precision castings,” ensuring that many titanium, aluminum and steel airframe castings have the strength needed for aircraft use without incurring defects or premature failure.

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.