HIP technology in power generation

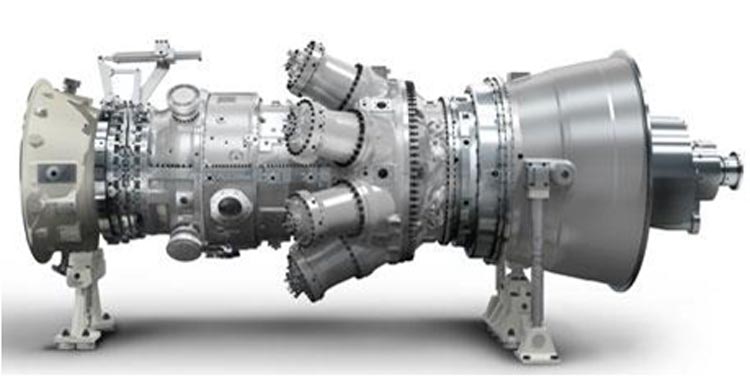

Hot isostatic pressing, born and developed for aerospace applications, is now also used extensively in the power generation sector, in particular on components of industrial gas turbines (both aeronautical and non-aeronautical) used in power plants. The requirements in this field are similar to those of aeronautics in terms of reliability and performance, but also present some key differences related to the different operating context. Below is an overview of similarities and differences in the use of HIP between aeronautical turbines and power turbines

Let's discover the similarities between the 2 sectors

Similarities to Aerospace: In both cases, HIP is used to densify critical castings and sinters, such as turbine blades and vanes, rotor discs and other structural components that operate at high temperatures. Industrial turbine components (such as power turbine blades) are often cast in similar superalloys to aerospace alloys and then HIPed to remove porosity, improving mechanical strength and preventing premature failure.

Just as in aircraft engines, in fact, eliminating internal voids extends the fatigue and creep life of the parts: the blades of a terrestrial turbine treated with HIP show greater strength and durability, since an internal defect is prevented from evolving into a crack during prolonged operation. Furthermore, in both the aeronautics and energy sectors, HIP allows to save expensive castings that would otherwise be rejected due to internal defects – a significant economic advantage given the high cost of these parts.

The materials treated are also often similar: nickel and cobalt superalloys for blades and disks, high-alloy steels for shafts and casings, titanium alloys (especially in aeroengine-derived turbines) – all materials that benefit from isostatic densification. In short, power generation turbines adopt HIP for similar purposes to aerospace: improving the metallurgical integrity of critical components, ensuring high performance and long-term reliability.

Differences between the aeronautical sector and power generationn

Main differences: Despite the similarities, there are operational differences. Stationary turbines tend to operate for very long cycles (continuous base-load regime), which places greater emphasis on long-term creep resistance than aircraft engines, which instead undergo numerous start/stop cycles (where cyclic thermomechanical fatigue is predominant).

This means that in industrial turbines HIP is particularly useful to prevent the formation of creep cavities in service: in some cases, worn land turbine blades have even been subjected to HIP rejuvenation to close micro-creep voids and extend their service life (a practice generally not adopted in the aeronautics field, where critical components are replaced preventively). Another difference concerns the design criteria: in aeroengines, weight minimization is crucial, so HIP allows to reduce safety oversizing due to defects, making the most of the material properties.

In stationary turbines the weight constraint is less stringent, but HIP is still used to reduce safety factors related to imperfections and allow more advanced designs or the use of larger castings instead of expensive forgings. In addition, on the materials side, the energy industry can sometimes adopt slightly different solutions: for example, some blades of large land turbines can be made of cast equiaxed alloy + HIP instead of monocrystalline, favoring lower costs and ease of production, in exchange for non-critical weights.

On the contrary, in cutting-edge aeronautical turbojets monocrystalline (SX) or directionally solidified blades are used, which are already optimized for creep/fatigue; these sometimes do not require HIP if the casting is perfect, or are treated with dedicated HIP cycles so as not to alter the crystalline orientation. In general, however, the technologies are interchangeable: many gas turbines for generation derive directly from aeronautical projects, bringing with them the same manufacturing and treatment processes (including HIP for blades, vanes and disks). In conclusion, HIP in energy applications plays a similar role to that in aeronautics – ensuring dense and reliable materials for high thermomechanical stress components – but adapting to the different priorities (continuous durability vs. lightweight) of each sector.

The similarities far outweigh the differences: whether it is about flying an airplane safely or spinning a turbine in a power plant, ensuring metallurgical excellence through HIP has become an established industry standard

Bring us your problems, our experience will provide the answers

We support and advise you in selecting the most suitable technology and materials to meet your specific needs.

Contact us now to have an engineer at your disposal, and together, we’ll find the solution to your biggest problems. We understand urgent, an engineer can be immediately available, call us, email us, and if necessary, you’ll have a proposal within 24 hours.